Releases: prusa3d/Prusa-Firmware-SL1

1.8.0-beta.0 Firmware for SL1 and SL1S SPEED

Summary

- Support for Prusa Connect

- Custom print profiles

- Updated PrusaLink Web

- Exposure time limits

- Reworked handling of USB flash drives

- API key support dropped

- Other improvements

- (M1 Customization for ModernDental)

- Bug fixes

- Known issues

Support for Prusa Connect

Starting this release 1.8.0 all the Original Prusa SLA printers can be controlled, monitored, and managed using cloud service - Prusa Connect.

There are three main ways how to register your machine into Prusa Connect:

- Touchscreen GUI on the printer

- Navigate into Settings -> Network -> Prusa Connect.

- Click on the “Add printer to Prusa Connect” button.

- Scan the QR code with your smartphone and proceed with the login to the Prusa Connect.

- Prusa Connect

- Find the Activation Code in the printer UI (Settings -> Network -> Prusa Connect)

- Login to Prusa Connect with a web browser.

- Click on “Add printer” and select your printer type from “SLA printers”.

- Enter your Code and optionally name your printer and location.

- PrusaLink

- Go to the “Settings” page.

- Click on the “Link” button. You will be automatically redirected to the Prusa Connect in a new tab.

Custom print profiles

With this firmware release, we are unlocking all parameters within print profiles for advanced users. This approach is a substitution for previously used print profiles (fast/slower/high viscosity)

The original intention for SL1S was to deliver closed, fine-tuned printing profiles to ensure a stable and easy user experience. However, with the growth of our material portfolio to include more specialized resins, we received requests from expert and R&D users to unlock these print profiles. As a result, we have now enabled users to modify each parameter separately rather than changing the entire set of settings. These parameters can also be edited in PrusaSlicer, starting from version 2.7.5.

All supported materials in PrusaSlicer have profiles fine-tuned by us. This feature is mainly intended for expert users.

Users can set or tune the parameters in PrusaSlicer (Expert mode) or in the printer before or during the print.

The printer does not need to measure the time for the separation process in the calibration wizard anymore. Calculation of these times is used instead. This may lead to better time estimation with errors in the maximum +- 3 % range.

Updated PrusaLink Web

PrusaLink web interface was updated to the latest version so you will get the same experience as on our other Original Prusa printers.

The main changes are:

- Settings page with the option to register the machine into Prusa Connect.

- Replaced REST API from legacy Octoprint like to Prusa “v1” API

Exposure time limits

With the latest resin development, we have found that some of them, especially the high-reactive ones, can be printed with even shorter exposure times than the existing limits allow. Therefore, we have lowered the bottom limits for the “Exposure time” and “Initial exposure” time to 0.1s.

Reworked handling of USB flash drives

Previously, USB thumb drives were connected to the system in read-only mode. To enable users to download files from Prusa Connect directly to the USB, drives are now mounted to the system in read-write mode, similar to how computers handle removable storage.

We have introduced a USB icon in the top bar. This icon indicates whether the drive is recognized by the printer or if the printer is currently writing to the drive.

We strongly recommend safely removing the drive before physically ejecting it. To do this, click on the USB icon and confirm the removal of the drive.

API key support dropped

Authentication from PrusaLink Web or PrusaSlicer is now possible only with HTTP Digest. API key authentication has been discontinued due to its lack of network security.

Other improvements

- Updated Linux kernel to version 5.16.11.

- Improved and optimized layer image preloader.

- SYSTEM SERVICE CRASHED error page in case some application exits during runtime.

- Area fill of the current layer is displayed while printing on the page with layer preview.

- Filemanager improvements

- The cache is directly driven by fs events for non-removable storages

- Removable storages are not watched (autounmout) and handled directly

Bug fixes

- Fixed QR code change after the error page was shown.

- Project reprint is forbidden when USB was unplugged before the project is copied into the internal memory.

- Fixed Booster board error after bootup.

- Fixed fan preprint check.

- Fixed unstable rear fan RPMs.

- Fixed missing M1 pictures in the wizards.

- Tank cleaning wizard can be started only on a calibrated printer.

- Factory reset:

- Fixed reset of the OTA update channel.

- Fixed network reset.

- Fixed NTP cannot be enabled after the FW update.

- Fixed emergency update. The printer now shuts down after an emergency reset.

- Fixed problems with the DHCP setting on the ethernet.

- Fixed manual setting of DNS for ethernet connection.

- Fixed overflowing text by swinging

- Fixed ethernet shows items only when a cable is connected.

- Fixed the back button on the RESIN LOW error page.

- Fixed unsafe path parsing in qtsvg(CVE-2021-45930)

Known issues

- The project downloaded from Prusa Connect to the USB drive is not shown in the Connect. The file is physically present and displayed correctly on the touchscreen GUI.

- Ejecting the USB before a project gets copied into the internal memory may lead to FW freeze. Rebooting the printer will resolve it.

- Downloading the file with the incompatible type (not .sl1s project) from PrusaLink Web shows an UNEXPECTED ERROR.

- Translations are not included in this build.

1.7.2 Firmware for SL1 and SL1S SPEED

Summary

- Project thumbnail page while printing

- Elephant foot and exposure times compensation fix

- Help pages split between M1 and SL1/S

- Red screen (error page) with a scrollable layout

- Bug fixes

- Known issues

This bugfix release includes multiple improvements and fixes across the entire firmware.

Project thumbnail page while printing

Added a new page with the project’s thumbnail accessible during the print. To access the Thumbnail screen you need to swipe twice to the right from the main screen.

Elephant foot and exposure times compensation fix

This FW modifies the behavior of the first few printed layers described by parameters: Faded layers, Initial exposure time and standard Exposure times in Prusa Slicer. The goal was to unify the interpretation of these entities between the slicer and the firmware. This makes it possible to better control the shape of the lower layers of the printed object and compensate for the undesirable elephant foot effect caused by the longer exposure time of the first layers.

CAUTION! Keep in mind that PrusaSlicer includes both the Initial exposure time layer and standard Exposure times layer into the Faded layers.

For example with:

- Faded layers = 5

- Initial exposure time = 10 s

- Exposure time = 1 s

- Elephant foot compensation = 1 mm

will be printed as (with this new FW): - 1st layer is compensated the most (by 1 mm) and exposed for 10 s.

- layers from 2nd to 4th are proportionally elephant foot compensated (by 0.75, 0.5 and 0.25 mm) and exposed for 7.75, 5.5 and 3.25 s.

- 5th layer is NOT compensated and exposed by standard Exposure time for 1 s.

Help pages split between M1 and SL1/S

The URL of Prusa Error Codes was changed to https://prusa.io/<error number> for SL1 and SL1S printers.

Red screen (error page) with a scrollable layout

The new error page layout is cleaned up and allows to show long error descriptions by a scrollable right portion of the page.

Bug fixes

- More explanatory error texts in Prusa Link Web.

- Simplified Prusa Error Codes text descriptions.

- Improved factory reset.

- Fixed update channel reset.

- Improved texts of the factory reset checks.

- Fixed inconsistent calibration - The user could end up with an uncalibrated printer right after passing the mechanical calibration wizard.

- When the project is not copied into internal memory yet, the print job now exits immediately when the user ejects the USB stick.

- Fixed occasional red screen #10320 Booster board after bootup.

- The emergency update turns the printer off instead of restarting.

- Fixed consistency of NTP settings on printer restarts.

Known issues

- If the tower gets stuck (or another unexpected event happens) during resin measurement, a resin sensor error is always reported, regardless of the real problem source.

- It is possible to run the Resin tank cleaning procedure on an uncalibrated printer. However, the wizard will fail and report the Cleaning adapter missing error.

- The RPM of the rear fan may oscillate during print if set to a lower RPM due to the automatic cooling of the UV LED.

- If the red error screen is displayed right after the startup (like #10601 BOOTED SLOT CHANGED), the QR code is not valid at first. It gets updated with a few seconds delay.

1.7.1 Firmware for SL1 and SL1S SPEED

Summary

- Fixed bugs

- Known issues

This is the final release of firmware 1.7.1 focusing primarily on bug fixes.

Fixed bugs

- PrusaLink now accepts only correct project extensions based on the printer type. Previously it was possible to open files with *.sl1 extension on the SL1S printer and vice versa. This was causing issues since both printers were using different settings for print.

- Some users reported that HTTP digest credentials (username/password) and/or API key were erased during firmware update. This is now fixed.

- Similarly to the previous bug, the network settings were erased during firmware update. Starting this firmware this issue shouldn't occur anymore.

- Various GUI glitches were fixed (overlaps in user interface).

- Long text labels in UI which are now scrolling slower, so they are more readable.

- Printer hostname now cannot start or end with a hyphen. This resolves a problem with standards inconsistency on the safe side.

- The packing wizard used while manufacturing the printer was regrouped to make it more robust.

Known issues

- If a tower gets stuck (or another unexpected event happens) during resin measurement, a resin sensor error is always reported, regardless of the real problem source.

1.7.0 Firmware for SL1 and SL1S SPEED

Summary

- Resin tank cleaning feature

- Improved resin calibration

- Print profile for high viscosity resins

- Improved behavior of the resin sensor

- Added option to cancel preprint checks

- OS version updated

- PrusaLink updated

- Bug fixes

- Known issues

This is the final release of firmware 1.7.0 introducing two new important features. Release notes include changes introduced in the first public release 1.7.0-beta.4. Compared to the previous major release 1.6.4, there are 24 bug fixes and 105 pull requests.

Resin tank cleaning feature

Once a print is finished, there might be enough resin in the tank to start another print immediately. However, there might be small parts laying at the bottom, invisible to the naked eye. Upon starting the next print, the print platform can push these parts against the FEP film and punch holes in it. For this reason, we recommend pouring the resin back into an empty bottle through a sieve and only then reusing the resin.

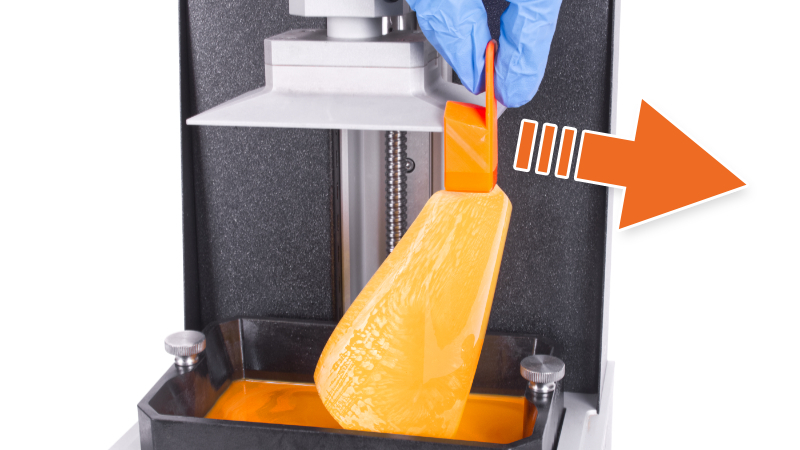

We are fully aware that this approach takes more time and this is why we are now testing a feature called “Resin tank cleaning”. When the print is finished, you can select this feature from the “finished” screen. Insert a special 3D printable adapter on the platform, wait while the printer lowers the platform and cures the first layer at the bottom of the tank (adjustable for 30-120 s). Once the curing is done, the platform rises up along with a thin layer of exposed resin attached to it.

IMPORTANT: Though this feature was heavily tested, it is not fully finished yet. While cleaning the tank, please always pay close attention to the printer to avoid possible issues. To learn more about this new feature, please see article Resin Tank cleaning.

Improved resin calibration

Even though we are constantly testing new resins and creating tailored print profiles, we are unable to cover all resins available to the market. With this release, we are bringing an option to run a calibration print, which will print multiple objects at different exposure times to help you decide, which value is the best for your resin.

During internal testing, we have discovered that the feature requires a major overhaul and this is why we have significantly updated the code and further extended its capabilities. Now, the printer is properly utilizing the HW acceleration to achieve improved precision and reliability.

The calibration object is now provided in three variants with different layer heights (0.025, 0.05 and 0.1 mm). To learn more about resin calibration please visit article Resin Calibration.

Print profile for high viscosity resins

The main aim of SL1S was to push the boundaries and increase the speed of SLA prints, in some cases the overall time is only 25 % of the previous generation SL1. However, in some cases, this speed is too high.

One example is professional resins with high viscosity. The SL1S in its default setting moves too fast and the resin is unable to flow and spread evenly under the print platform. Since this is a physical property of the material and can't be changed, we are adding another option “High Viscosity” to already existing profiles “Faster” and “Slower”.

Resin sensor improved behavior

Previously, when the resin sensor failed, the system halted with an error. Now the printer repeats the action two more times before reporting an error. We would like to thank the users who suggested this change.

Canceling preprint checks

Until now, when the pre-print checks were running, the user wasn't able to cancel them. From our experience, you might realize you haven't prepared the printer properly and the checks will inevitably fail. For this reason, we are now adding an option to cancel the checks at any time and return back to the menu.

PrusaLink updated

The overall look of the web interface PrusaLink is now unified across our printers (FDM/SLA). Sidebar parameters include the status of the printer. Also, starting this release, users can also download the project from a remote URL directly into the printer.

OS version updated

The SL1 and SL1S are based on a forked version of Debian Linux and as a part of regular maintenance, the developers have updated this part of the system. Yocto version 3.1 Dunfell was replaced by 3.4 Honister. This means Linux kernel 5.15 is used instead of 5.11. The new version brings improved performance and security.

Bug fixes

- The web user interface PrusaLink could freeze when attempting to print on an uncalibrated printer. Now, the printer recognizes the uncalibrated state and asks the user to perform it first.

- In certain situations, the logic of automated fan speed control was not disabled during fan tests. This could have resulted in an incorrectly failed test. The algorithm was adjusted to work correctly.

- Incorrect (less than a minute) print time was sometimes reported by the printer after the auto switch-off was switched on again.

- After changing the language of the user interface, the printer had to be restarted for month names to reflect the change. This was fixed, the language change propagated instantly.

- The LED test was not carried out before printer calibration. Devs have corrected the order of tests for this release.

- In the “Printer calibration tilt adjust” screen, the OK button was incorrectly shifted and cropped for Spanish, French and Italian. Now, it is displayed correctly.

- Project previews of the files uploaded by Prusa Link were sometimes not displayed. The issue was detected and corrected.

- The QR codes in the “About us” screen were pointing to the English web page even when the printer was set to another language. Now, the URL link in the QR code is changed correctly based on the selected system language.

- After a certain rare sequence of upgrades, slot swaps and failed calibrations it was possible to start printing on an uncalibrated printer.

- Security and network tokens are remembered after firmware upgrades. Prior to this fix, they had to be re-entered after each upgrade.

- PrusaLink now handles files with respect to filename extensions correctly before it was possible to initiate the upload of files that were incompatible with the printer model.

- The printer's “Hostname” is now being checked for correct format while entered by the user.

- A factory reset is now no longer deleting the Ethernet default configuration.

- The date encoded in the log file name now includes the day of the month.

- Error reporting was inconsistent while measuring resin. Resin sensor error was incorrectly reported in some cases, instead of tower failure. This behavior is now fixed.

- Some UI elements were improperly cropped. Developers checked and fixed all known occurrences.

- The network interface was not properly showing the Wi-Fi or Ethernet set-up screen. The interface has been reworked. The network settings menu screen shows IP addresses directly.

- The network search protocol did not work properly. Now the PrusaSlicer should be able to find the printer on your local network without any issues.

- Some UI elements were overflowing horizontally if translations were much longer than the English original. This is now fixed.

- Sounds (beeps) during the Resin Tank Cleaning setup were inconsistent with the rest of the user interface. This issue first appeared in the beta.4 release and was corrected.

- With some error messages, the printer did not beep. Starting this firmware the behavior should be as expected.

- Until now, the printer did not display an error when printing on an uncalibrated printer was attempted from PrusaLink. The error message is now correctly displayed.

- Due to incorrect rounding, the remaining and consumed resin amounts were incorrect. The algorithm behind these calculations was revised for this release

- In certain scenarios, the PrusaLink did not show the content of a USB flash drive. Should this repeat, please let us know.

- The high viscosity profile, introduced in 1.7.0-beta.4 occasionally failed due to a too high tower sensitivity setting. This feature was fine-tuned for this final release.

- Hardware configuration errors at boot time were not reported correctly and it was necessary to reboot the printer in certain situations.

- The order of checks in the Wizard was changing between runs and was not consistent.

Known issues

- In a cold environment (18 °C and below), the printer may report a fan error incorrectly during the preprint checks and allow the user to print. However, it is recommended to keep the printer in a room with an ambient temperature of 18-32 °C

- Some settings are applied only after the printer is restarted. These include fan speed and tower sensitivity.

1.6.6 Firmware for SL1 and SL1S SPEED

Summary

- Support for new rear fan

- Support for new DAC converter

This is a final firmware release focused on support for new hardware due to parts shortages. Upgrading to this firmware is required only in case you are currently upgrading your SL1 to SL1S or replacing HW parts described below.

Version 1.6.6 is a direct successor to the previous final version 1.6.4. Version 1.6.5 was not released publicly as it was used for internal purposes only.

Support for new rear fan

Our vendor started supplying new rear fan with slightly different specifications. Self-tests and RPM control in the firmware were adjusted to accommodate this change. There is no change from the user's perspective, only a slight audible difference. This adjustment in the firmware makes the new rear fan backward compatible with SL1 and SL1S SPEED.

Support for new DAC converters

There is a shortage of digital-to-analog converter (DAC) used on the boost board in the SL1S SPEED. This part is now replaced with an equivalent DAC, however, some changes to the firmware were required.

If you install this new revision of the boost board to a printer running firmware 1.6.5 or older, the system will display an error message #10320. To fix this issue, please install this firmware release 1.6.6.

1.7.0-beta.4 Firmware for SL1 & SL1S

Summary

- Resin tank cleaning feature

- Improved resin calibration

- Print profile for high viscosity resins

- Improved behavior of the resin sensor

- Added option to cancel preprint checks

- OS version updated

- PrusaLink updated

- Bug fixes

- Known issues

This is the first public beta release of the upcoming firmware 1.7.0, which brings two new important features. Compared to the previous release 1.6.4, there are 24 bug fixes and 105 pull requests. Please note that this firmware is recommended to the advanced users.

Resin tank cleaning feature

Once a print is finished, there might be enough resin in the tank to start another print immediately. However, there might be small parts laying at the bottom, invisible to the naked eye. Upon starting the next print, the print platform can push these parts against the FEP film and punch holes in it. For this reason, we recommend pouring the resin back into an empty bottle through a sieve and only then reusing the resin.

We are fully aware that this approach takes more time and this is why we are now testing a feature called “Resin tank cleaning”. When the print is finished, you can select this feature from the “finished” screen. Insert a special 3D printable adapter on the platform, wait while the printer lowers the platform and cures the first layer at the bottom of the tank (adjustable for 30-120 s). Once the curing is done, the platform rises up along with a thin layer of exposed resin attached to it.

IMPORTANT: Though this feature was heavily tested, it is not fully finished yet. While cleaning the tank, please always pay close attention to the printer to avoid possible issues. To learn more about this new feature, please see article Resin Tank cleaning.

Improved resin calibration

Even though we are constantly testing new resins and creating tailored print profiles, we are unable to cover all resins available to the market. With this release, we are bringing an option to run a calibration print, which will print multiple objects at different exposure times to help you decide, which value is the best for your resin.

During internal testing, we have discovered that the feature requires a major overhaul and this is why we have significantly updated the code and further extended its capabilities. Now, the printer is properly utilizing the HW acceleration to achieve improved precision and reliability.

The calibration object is now provided in three variants with different layer heights (0.025, 0.05 and 0.1 mm). To learn more about resin calibration please visit article Resin Calibration.

Print profile for high viscosity resins

The main aim of SL1S was to push the boundaries and increase the speed of SLA prints, in some cases the overall time is only 25 % of the previous generation SL1. However, in some cases, this speed is too high.

One example is professional resins with high viscosity. The SL1S in its default setting moves too fast and the resin is unable to flow and spread evenly under the print platform. Since this is a physical property of the material and can't be changed, we are adding another option “High Viscosity” to already existing profiles “Faster” and “Slower”.

Resin sensor improved behavior

Previously, when the resin sensor failed, the system halted with an error. Now the printer repeats the action two more times before reporting an error. We would like to thank the users who suggested this change.

Canceling preprint checks

Until now, when the pre-print checks were running, the user wasn't able to cancel them. From our experience, you might realize you haven't prepared the printer properly and the checks will inevitably fail. For this reason, we are now adding an option to cancel the checks at any time and return back to the menu.

PrusaLink updated

The overall look of the web interface PrusaLink is now unified across our printers (FDM/SLA). Sidebar parameters include the status of the printer. Also, starting this release, users can also download the project from a remote URL directly into the printer.

OS version updated

The SL1 and SL1S are based on a forked version of Debian Linux and as a part of regular maintenance, the developers have updated this part of the system. Yocto version 3.1 Dunfell was replaced by 3.4 Honister. This means Linux kernel 5.15 is used instead of 5.11. The new version brings improved performance and security.

Bug fixes

- The web user interface PrusaLink could freeze when attempting to print on an uncalibrated printer. Now, the printer recognizes the uncalibrated state and asks the user to perform it first.

- In certain situations, the logic of automated fan speed control was not disabled during fan tests. This could have resulted in an incorrectly failed test. The algorithm was adjusted to work correctly.

- Incorrect (less than a minute) print time was sometimes reported by the printer after the auto switch-off was switched on again.

- After changing the language of the user interface, the printer had to be restarted for month names to reflect the change. This was fixed, the language change propagated instantly.

- The LED test was not carried out before printer calibration. Devs have corrected the order of tests for this release.

- In the “Printer calibration tilt adjust” screen, the OK button was incorrectly shifted and cropped for Spanish, French and Italian. Now, it is displayed correctly.

- Project previews of the files uploaded by Prusa Link were sometimes not displayed. The issue was detected and corrected.

- The QR codes in the “About us” screen were pointing to the English web page even when the printer was set to another language. Now, the URL link in the QR code is changed correctly based on the selected system language.

- After a certain rare sequence of upgrades, slot swaps and failed calibrations it was possible to start printing on an uncalibrated printer.

- Security and network tokens are remembered after firmware upgrades. Prior to this fix, they had to be re-entered after each upgrade.

- PrusaLink now handles files with respect to filename extensions correctly. Before it was possible to initiate the upload of files that were incompatible with the printer model.

- The printer's “Hostname” is now being checked for correct format while entered by the user.

Known issues

- The system may not correctly distinguish and report the difference between a homing error and a resin sensor error during resin level measurement.

- Texts in GUI and PrusaLink are not fully reviewed and translated to all languages for this beta release.

1.6.4 Firmware for SL1 and SL1S SPEED

Summary

- Added support for the medical printer

- Bug fixes

This is the final release of firmware 1.6.4 focused primarily on fixing the bugs in the code. Compared to the previous release 1.6.3, there are 105 pull requests.

Added support for the medical printer

This release extends support for the upcoming Prusa MSLA printer, which will specialize in the medical segment. Due to some differences in the workflow, the developers have branched the code allowing for firmware adjustments without affecting the user experience while using the SL1S SPEED.

Bug fixes

Reading invalid files behaviour fixed

In the previous versions, an attempt to read an invalid file led to a deadlock, requiring a printer restart. The error handling was fixed.

Exposure time adjustment error

In the print settings, changing the exposure time led sometimes to erratic behavior due to rounding errors in communication on the dbus. This is now fixed.

Factory reset didn't include screen brightness

The screen brightness of the touch screen was stored in a different place than the rest of the configuration values and was not reset with a factory reset. This was rectified and now the factory reset is performed correctly.

Inconsistent logging from motion controller

Certain information/confirmation messages from the motion controller were incorrectly logged as warnings. Since the purpose of the log is to store faults and errors, those messages will not be logged anymore.

MC firmware update notification missing

The notification during the Motion Controller firmware update process was missing. Now this message is correctly displayed.

Tilt home succeeded with disconnected tilt

Users have reported that in certain situations tower homing failed after a hardware upgrade and complicated adjustments of tower sensitivity were necessary to correct it. Version 1.6.4 handles this correctly.

Downloading logs to disconnected USB drive

When trying to download system logs to USB without a USB flash drive connected an incorrect message “Printer is OK” was displayed. Now, the printer behaves correctly and informs the user about the missing USB storage.

1.6.3 Firmware for SL1 and SL1S SPEED

Summary

- Preprint workflow changed

- Print profile selection added to PrusaLink

This is the final release of firmware 1.6.3. There are two changes in the user interface and several bug fixes. Compared to the previous release 1.6.2, there are five commits and three pull requests. We consider this a bugfix release.

Preprint workflow changed

The preprint workflow is made safer and faster, compared to past firmware releases. Previously, the printer sometimes left the tank tilted down and it was more difficult to pour in the exact amount of resin since the user was unable to use the engraved levels (50, 75, 100 %).

Now, once the user confirms he wants to continue and print the selected project, the printer homes (levels) the tank and asks the user to check the amount of resin. Once the amount is confirmed, the printer proceeds with pre-print checks and starts printing. The same procedure is included in the web interface for a remote print.

Print profile selection added to PrusaLink

Similar to the user interface in the printer, the user can now switch between the Faster and Slower print profiles from the web interface PrusaLink.

If a user runs into trouble while printing unusually large and complex objects, it may be necessary to turn on the slower mode. Just like in the UI on the printer, the Faster profile is the default, while the Slower profile adjusts the parameters for safer quality printing. For example, hollow or larger thin-walled models.

1.6.2 Firmware for SL1 and SL1S SPEED

Summary

- Fixed factory reset

The firmware is compatible with both SL1 and SL1S SPEED.

Fixed factory reset

During factory reset, the axis sensitivity parameters were cleared incorrectly. Axis sensitivity remained internally stored even after factory reset if it was set to a non-zero value. This bug is now fixed.

1.6.1 Firmware for SL1 and SL1S SPEED

Summary

- New print display driver

- Support for diacritics in filenames

- Improved display counter

- PrusaLink improvement

- Preprint checks

- Increased space for user prints

- Other improvements and bug fixes

This is a final release of firmware 1.6.1 focusing on improvements and fixing bugs found during extensive internal testing. The firmware is compatible with both SL1 and SL1S SPEED.

New print display driver

The developers have tested and deployed an improved driver, which is responsible for controlling the monochrome print display. This upgrade ensures a more robust data connection between A64 graphics and the screen preventing any possible flickering.

Support for diacritics in filenames

The majority of the print projects are named using a standard character set. However, in some countries like the Czech Republic, special characters with diacritics are used (e.g. č, ř, ž). Using any of these characters was causing issues on the previous firmware release. Developers have extended the character support and fixed this issue.

Improved display counter

During internal testing, it was discovered that in some edge cases the display counter doesn't work properly. Most of those situations were connected with replacing the print display. To ensure the counter is working in all cases, developers had rewritten most of the code responsible for this feature.

PrusaLink improvement

The web interface PrusaLink is capable of displaying error messages, however, the system sometimes displayed the same error message multiple times. The handling of the messages is now improved and should work properly.

Preprint checks

In some cases, the resin tank might be tilted before the print is started making it harder to pour the exact amount of resin. For this reason, immediately after the print is started by the user, the printer first makes sure that the tank is leveled and asks for refilling the resin if necessary.

Increased space for user prints

The size of the system logs was optimized and limited in order to provide more storage for the user prints. Upon the next printer boot, the system will clean up older logs resulting in 348 MB of additional space.

Other improvements and bug fixes

- Continuous Integration (CI): add static analysis to improve automatic tests

- For developers: added QtCreator configuration script to help devs while building and running GUI on a computer

- Improved translations and automatic checks to ensure the same formatting of the translation as the source

- Custom time format added. Users can pick native format tied to the selected language or force 24-hour/12-hour format.

- fix: other screens are no longer “flickering” into the Wizard

- fix: axis sensitivity is now updated and stored immediately after a user change

- fix: print time estimates are now always showing only positive values

- fix: unified printer name on the firmware update screen

- fix: RPM change of each fan is now applied immediately

- fix: while on Waitscreen the system now ignores additional touches

- fix: prevent a user from running multiple reprints at once, previously causing an error

- fix: increased size of "view examples" button

- fix: DBus (suppress unneeded signals + improved error handling)